How to Choose the Right Abrasive for Each Industrial Process: A Clear and Practical Technical Guide

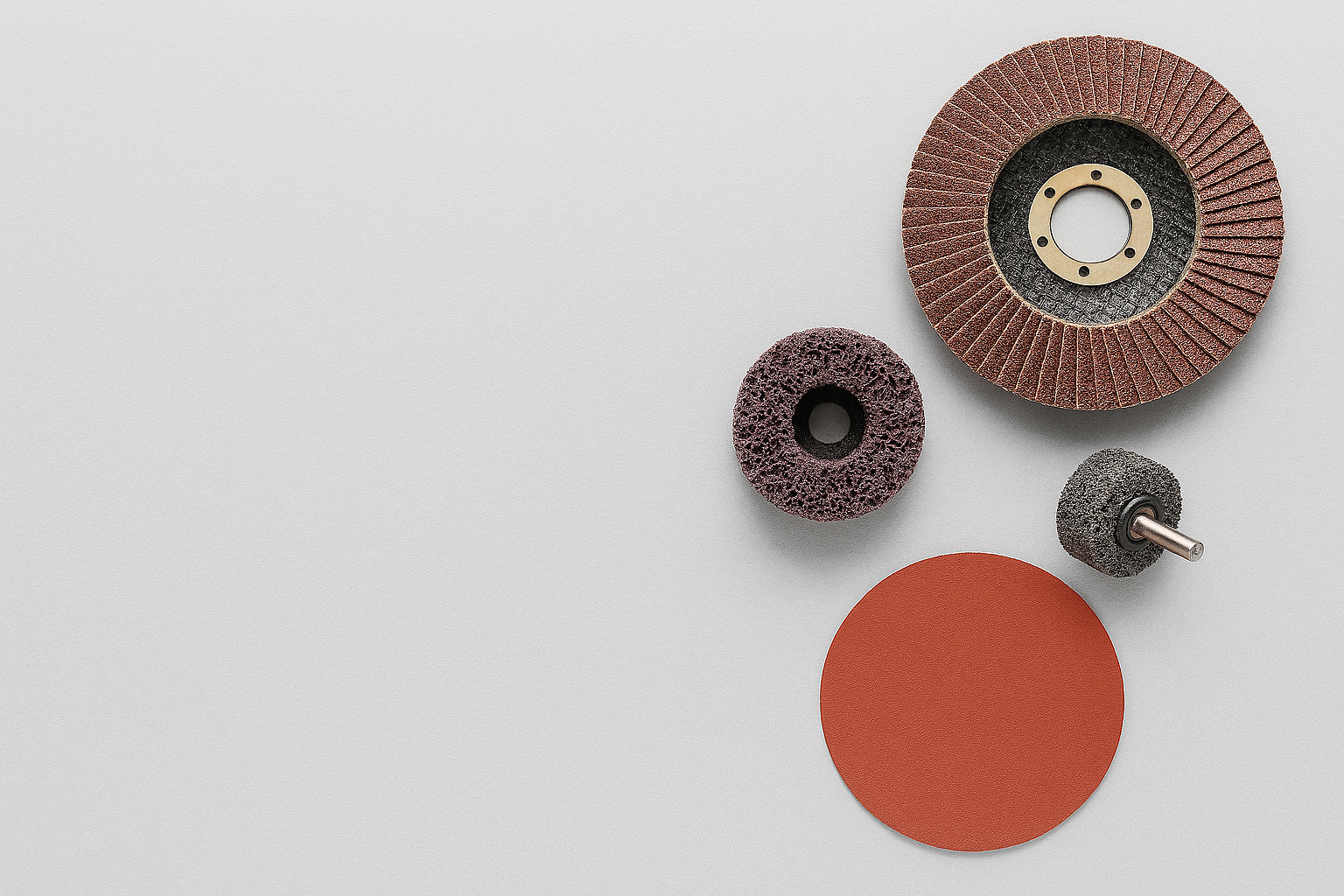

Choosing an abrasive is not simply picking ‘a sheet’ or ‘a disc.’ In any industrial environment—foundry work, machining, metal fabrication, aluminum, or stainless steel—the right selection directly affects productivity, surface quality, and cost per part.

Choosing an abrasive is not simply a matter of picking “a sheet” or “a disc.” In any industrial environment—foundry work, machining, metal fabrication, aluminum, or stainless steel—the right selection directly affects productivity, surface quality, and cost per part. This guide explains, in a technical yet accessible way, the factors that determine which abrasive is best suited for each process.

1. Understanding the abrasive grain: the heart of performance

The grain is the element that actually does the work. Its properties determine how it cuts, how long it lasts, and how it behaves under pressure.

Hardness

Hardness defines the grain’s ability to penetrate the material.

Aluminum oxide offers a balance between performance and durability.

Silicon carbide is harder and performs very well on aluminum and non‑ferrous materials.

Micro‑fracturing ceramic grains are the most advanced: they “self‑sharpen” and maintain a consistent cut even on difficult alloys.

Toughness

Toughness indicates how much the grain resists breaking.

A high‑toughness grain is ideal for aggressive stock removal.

A less tough grain fractures in a controlled way, keeping the cutting edge sharp for longer—especially useful on stainless steel.

Grain shape

Geometry also matters:

Sharp grains cut fast.

Blocky grains last longer.

Micro‑fracturing grains combine both advantages.

2. Backing and structure: more important than they seem

The backing doesn’t just hold the grain—it determines the abrasive’s flexibility, rigidity, and stability.

Types of backing

Vulcanized fiber: rigid, ideal for grinding discs.

Polyester: heat‑ and tear‑resistant.

Cotton: flexible, perfect for fine finishing.

Three‑dimensional nylon: enables controlled deburring and very uniform finishing.

Structure

An open structure prevents loading, essential for aluminum.

A closed structure is more aggressive and works well on steel.

High‑density structures (such as unitized) are ideal for edges and corners.

Low‑density structures are used for cleaning and soft finishing.

3. Working parameters: where performance is won or lost

Even the best abrasive can perform poorly if used under the wrong conditions.

Peripheral speed

Each abrasive type has an optimal speed range. Below it, efficiency drops; above it, heat increases and lifespan decreases.

Applied pressure

With high pressure, rigid and aggressive abrasives work best.

With low pressure, flexible or three‑dimensional abrasives perform better.

Temperature

Heat is one of the biggest enemies of both the abrasive and the material. Excess heat can cause burns, deformation, or contamination on stainless steel. Ceramic grains and anti‑loading coatings help keep temperature under control.

4. How to choose the abrasive according to the process

Foundry

Operations are heavy: removing risers, flash, and casting skin. Ceramic grinding discs, high‑density unitized wheels, and three-dimensional abrasives for final finishing work very well.

Steel machining

Typical tasks include deburring, weld preparation, and intermediate finishing. Zirconia or ceramic flap discs, ceramic belts, and high‑quality fiber discs are the most reliable options.

Aluminum

The main issue is loading. To avoid it, use silicon carbide grains, open structures, and anti‑loading coatings. Three - dimensional abrasives also perform very well for finishing.

Stainless steel

A material sensitive to heat and contamination. Micro‑fracturing ceramic grains, 3D abrasives for satin finishing, and unitized wheels for edges deliver very consistent results.

5. Evaluating the real cost: beyond the abrasive’s price

Cost per part depends on:

Abrasive lifespan

Process stability

Reduction of rework

Changeover time

Final surface quality

A higher‑quality abrasive can reduce total production cost even if its unit price is higher.

Conclusion

Choosing the right abrasive is a technical decision that combines material, process, and working parameters. When these factors are properly analyzed, the result is a more stable process, a more uniform finish, and a lower cost per part. At Abramaster, we help companies identify the abrasive solution that best fits each application, always with a practical approach focused on real world performance.