Rotary carbide burrs

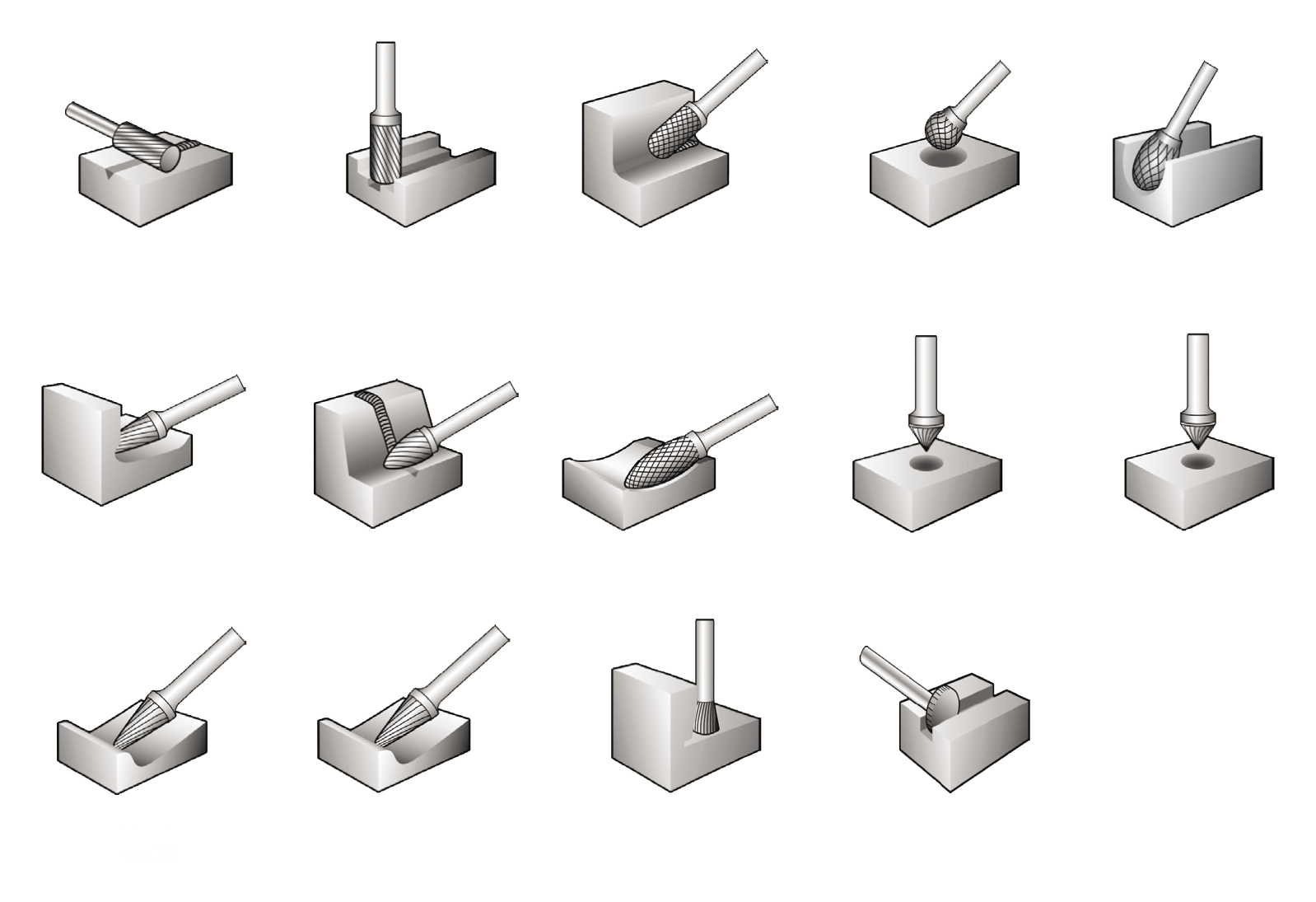

Our wide range of carbide barrs covers the various shapes, offering optimal results in preparing and removing weld seams, beveling and deburring in the shipbuilding, automotive, petrochemical, nuclear, foundry and aviation industries. Specially designed geometries meet the most demanding requirements in stainless steel, steel, cast steel, aluminium and composite applications providing fast material removal and long life with maximum efficiency.

Our innovative premium cutting types such as the "Blue Power", designed for very demanding applications in heavy industries such as shipbuilding, wind power or heavy aplications, with material removal capacity and durability never seen before, or our special cutting range for aluminium "Alu Tech" optimised with a special lubricant coating that generates less heat and reduces clogging, considerably extending the tool's life, all manufactured with a carefully designed handle joint, always ensuring safe working with low vibration levels and maximum performance.

Premium cutting types

Standard cutting types

FORMS